- Overview

- Product Description

- Relateed Products

- Company Profile

- Cooperatine Supplier

- Product Process Control

- Sales Network

- Our Service

Basic Info.

Product Description

steel. Simple operation, high production efficiency.

Technical specification of APM2020A

| Angle size | 63mm×63mm×4mm ~ 200mm×200mm×20mm |

| Max. punching diameter | φ25.5mm(20mm thickness, Q345) |

| Nominal punching force | 1100KN |

| Quantity of punching head per side | 3 |

| The quantity of punching row per side | arbitrariness |

| The quantity of character group | 4 groups |

| Dimension of characters | 14×10mm(10) |

| Nominal Marking force1030KN | 1030KN |

| Max. length of the raw angle | 14m |

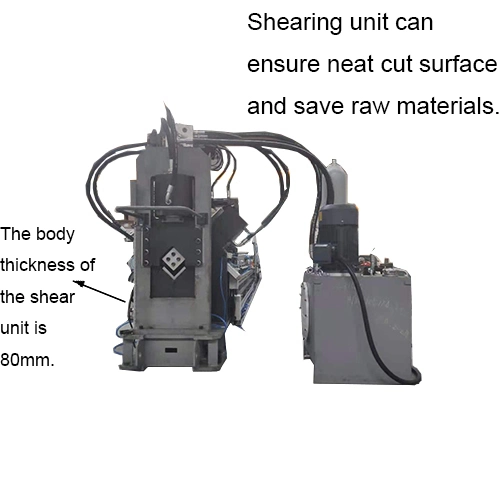

| Cutting mode | Double-blade shearing |

| Nominal Shearing force | 1800KN |

| Quantity of CNC axes | 3 |

| Angle feeding Speed | 40m/min, the efficiency is about 1000 holes/hour |

| Hydraulic station cooling method | air cooling |

The finished angle conveyor is rotated to one side by pneumatic power. The max. Length of finished angle is 8 m.

There are four transverse conveyors which can infeed automatically.

Type of programming: Keyboard input, USB interface input, floppy disc input.

Power: Three phase four wire system

AC Voltage: 380V

Fluctuation of voltage: ± 10%

Frequency: 50 Hz

| Serial No. | Name | Brand | Country |

| 1 | AC Servo Motor | Panasonic | Japan |

| 2 | Orientation module | Mitsubishi | Japan |

| 3 | PLC | Mitsubishi | Japan |

| 4 | Unloading valve | ATOS/YUKEN | Italy/Taiwan |

| 5 | Relief valve | ATOS/YUKEN | |

| 6 | Electro-hydraulic directional valve | ATOS/YUKEN | |

| 7 | Solenoid reversing valve | ATOS/YUKEN | |

| 8 | Single direction valve | ATOS/YUKEN | |

| 9 | Valve plate | SMC/CKD | Japan |

| 10 | Air valve | SMC/CKD | |

| 11 | Cylinder | SMC/CKD | |

| 12 | Triple joint | SMC/CKD | |

| 13 | Computer | LENOVO | China |

Shandong FIN C N C MACHINE CO., LTD is located in Jinan high tech Development Zone, is committed to the development, research, design, manufacture, sales of CNC machine tools, such as processing angle bar, beam channel profiles, steel plates, tubesheet and flanges. It is mainly used in iron tower, steel structure, heat exchanger, boiler, bridge, truck and other industries.FIN CNC machines exported to 50+ countries across globe market. Our company has strong R & D center with 30 engineers team, they have 20 years of experience ; 280 staff, plant area about 270,000 sqm. Main products: CNC Angle Line, CNC Beam Drilling Sawing Machine, CNC Plate Drilling Machine, CNC Rail Processing Machine, CNC Tubesheet Flange Drilling Machine, Truck beam plate punching machine. The company drafted many China national standards for C N C angle line

1. When can you arrange shipment?

For machines available in stock, the shipment can be arranged within 15 days after getting advance payment or L/C;

For machines non available in stock, the shipment can be arranged with 60 days after getting advance payment or L/C.

2. What can you do if my machines have problems?

1) We can send you free components if machines are in warranty period;

2) 24 hours service on line;

3) We can assign our engineers to serve you if you want.

3. Do you provide machine operation training?

Yes. We can send professional engineers to the working site for machine's installation, commissioning and operation training.

4. Which machine model shall I choose when I purchase from you?

Please share us your material size and your processing request, then we will recommend our machine most suitable and most cost effective for your work demand.

5. What's your machine's market share in China?

Our market share in China is about 70%+, and we've exported to 50+ countries across the globe market, since year 1998.