Basic Info.

Model NO.

400-3500

Feature2

Printing and Dyeing Industry

Feature3

400-3500 Series

Sample

Free Sample (Small Scale)/ Shipping on Your Own

Transport Package

Land, Sea and Air Freight

Specification

400*400-2000*2000

Trademark

FUJIE

Origin

China

Production Capacity

10000

Product Description

Product description

Box type filter plate, with filter chambers on both sides, each filter plate is a filtering unit. Suitable for most industries, with characteristics such as fast filtration speed and high filtration pressure. The suitable concentration of solid particles in the suspension is generally below 10%, and the operating pressure is generally 0.3-0.6 MPa. In special cases, it can reach 3 MPa or higher. There is a large feeding hole in the middle of the box plate, which allows for fast and even feeding, and is not easy to block, causing uneven pressure between the filter chambers. This is important for applications with high feed volume or pressure. Because the sealing surface of the filter plate is tightly fitted, it will not deform under high pressure. In addition, the box filter press is more convenient for unloading mud.

Simple structure, easy operation, stable operation, and convenient maintenance. Less vulnerable parts, convenient replacement of filter cloth, low maintenance cost, flexible selection of filter area, small footprint, strong adaptability to materials, suitable for various small and medium-sized sludge dewatering treatment occasions. Multiple automation devices can be configured, with a high degree of automation

High pressure filtration, lower material moisture content. Fast filtration speed and uniform washing of filter cake. The filtrate is clear and the solid recovery rate is high. Simple structure, low failure rate, and easy maintenance and management

The company provides all series from 400mmX400mm to 3500mmX3500mm

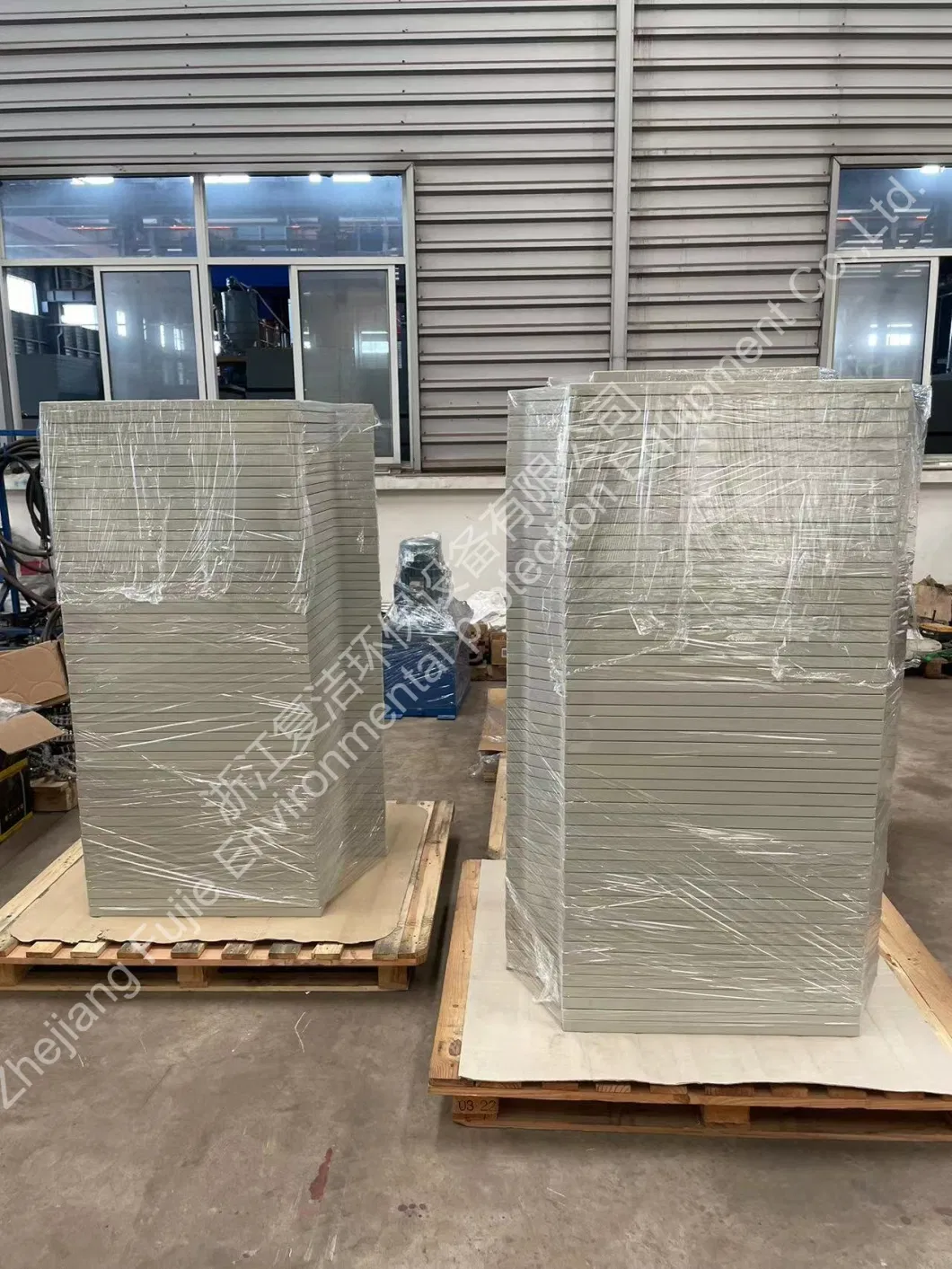

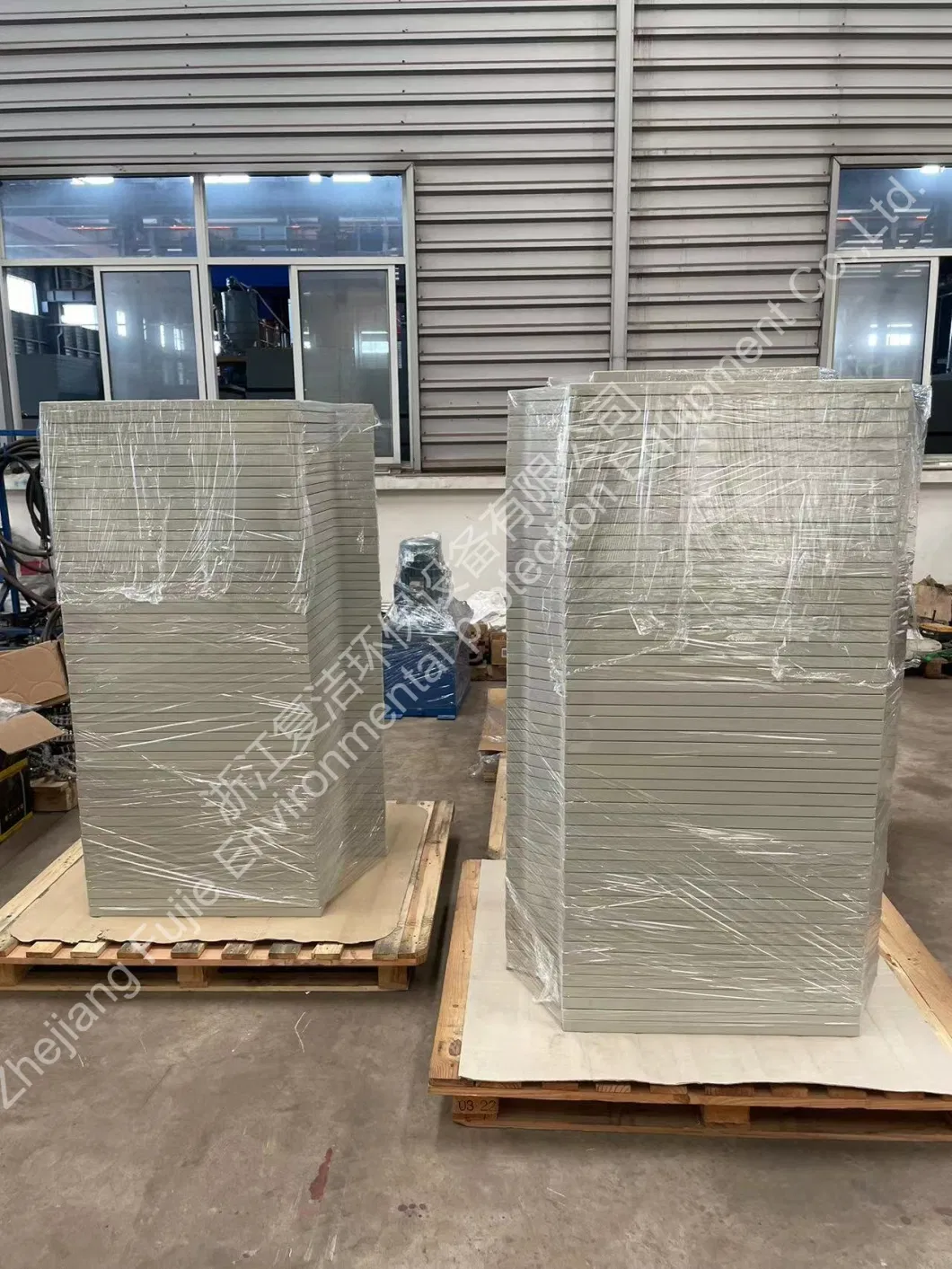

Product display

1.Parameter differs in each model because of various requirements (high temperature ,chemical resistance)

2.Customization available.

3.Please contact us for any further information

About us

Box type filter plate, with filter chambers on both sides, each filter plate is a filtering unit. Suitable for most industries, with characteristics such as fast filtration speed and high filtration pressure. The suitable concentration of solid particles in the suspension is generally below 10%, and the operating pressure is generally 0.3-0.6 MPa. In special cases, it can reach 3 MPa or higher. There is a large feeding hole in the middle of the box plate, which allows for fast and even feeding, and is not easy to block, causing uneven pressure between the filter chambers. This is important for applications with high feed volume or pressure. Because the sealing surface of the filter plate is tightly fitted, it will not deform under high pressure. In addition, the box filter press is more convenient for unloading mud.

Simple structure, easy operation, stable operation, and convenient maintenance. Less vulnerable parts, convenient replacement of filter cloth, low maintenance cost, flexible selection of filter area, small footprint, strong adaptability to materials, suitable for various small and medium-sized sludge dewatering treatment occasions. Multiple automation devices can be configured, with a high degree of automation

High pressure filtration, lower material moisture content. Fast filtration speed and uniform washing of filter cake. The filtrate is clear and the solid recovery rate is high. Simple structure, low failure rate, and easy maintenance and management

The company provides all series from 400mmX400mm to 3500mmX3500mm

Product display

Filter cloth workshop

Our Advantages

1.Rich in sizes and models, almost covering any needs of various industries

2.We have good cooperation experience with major clients around the world. According to your requirements, we can fully customize the most suitable filter plate and filter machine for you, and choose the best solution for you.

3. High cost-effectiveness, acceptable for sample orders

4. Fast delivery time and attitude towards solving problems quickly

5. Our company's box type filter press filter plate uses PP raw material for enhanced and modified production process. After

one-time molding, it undergoes post-treatment processing to achieve acid, alkali, and temperature resistance. The specifications include center feed, upper middle feed, and corner feed. The filter plate is equipped with 4-8 compression support points, making it more compressive.

6. Good sealing, anti leakage, odorless and non-toxic, with excellent service life

Specifications

1.Rich in sizes and models, almost covering any needs of various industries

2.We have good cooperation experience with major clients around the world. According to your requirements, we can fully customize the most suitable filter plate and filter machine for you, and choose the best solution for you.

3. High cost-effectiveness, acceptable for sample orders

4. Fast delivery time and attitude towards solving problems quickly

5. Our company's box type filter press filter plate uses PP raw material for enhanced and modified production process. After

one-time molding, it undergoes post-treatment processing to achieve acid, alkali, and temperature resistance. The specifications include center feed, upper middle feed, and corner feed. The filter plate is equipped with 4-8 compression support points, making it more compressive.

6. Good sealing, anti leakage, odorless and non-toxic, with excellent service life

Specifications

| Feeding | Model | Plate Thickness (mm) | Board thickness (mm) | Inlet diameter (mm) | Inlet thickness (mm) | Washing hole size (mm) | Maximum feed pressure (MPa) | Standard drivepipe | Open flow PP Water faucet | ||||||

| ≤50 | ≤75 | ≤90 | ≤110 | ||||||||||||

| ºC | ºC | ºC | ºC | ||||||||||||

| Center | X250 | 25 | 50 | 32 | 25 | 20 | 2 | 1.6 | 1 | 0.4 | <1MPa: PP; >90ºC, >1MPa T 304 | 1/2 | |||

| Center | X400 | 25 | 50 | 62 | 20 | 32 | 2 | 1.6 | 1 | 0.4 | |||||

| Center | X630 | 30 | 60 | 70 | 20 | 50 | 1 | 0.8 | 0.6 | 1/2 | |||||

| 25 | 55 | 70 | 20 | 50 | 1 | 0.8 | 0.6 | ||||||||

| Center | X800 | 30 | 60 | 90 | 30 | 50 | 1 | 0.8 | 0.6 | PP | 1/2 | ||||

| 20 | 50 | 90 | 30 | 50 | 1 | 0.8 | 0.6 | ||||||||

| 25 | 55 | 90 | 30 | 50 | |||||||||||

| Center | X1000 | 30 | 60 | 85 | 50 | 1 | 0.8 | 0.6 | 304 | 1/2 | |||||

| 25 | 55 | 85 | |||||||||||||

| 35 | 65 | 70 | |||||||||||||

| Center | X1250 | 30 | 60 | 130 | 30 | 65 | 0.6 | 0.4 | 0.2 | PP/304 | 1/2 | ||||

| XI1250 | 30 | 60 | 130 | 30 | 65 | 1 | 0.8 | 0.6 | |||||||

| Center | 10X1500 | 35 | 70 | 150 | 30 | 80 | 1 | 0.8 | 0.6 | PP | 3/4 | ||||

| 30 | 65 | 150 | 30 | 80 | 1 | 0.8 | 0.6 | ||||||||

| 16X1500 | 35 | 75 | 150 | 35 | 80 | 1 | 1.6 | 1 | 0.6 | ||||||

2.Customization available.

3.Please contact us for any further information

Product catalog

About us

Zhejiang Fujie Environmental Protection Equipment Co., Ltd. was established in June 2016 and is a wholly-owned subsidiary of Shanghai Fujie

The company has 60000KN, 80000KN, and 120000KN ultra large injection and pressure equipment, with the largest tonnage of oil pressure machines in the industry and multiple three axis machining centers and several five axis machining centers, making it the first enterprise in the industry to use five axis machining.

The unique raw materials and formulas for filter plate manufacturing ensure various performance indicators and mechanical strength, and the material is uniform and dense. The company has passed three major management system certifications: ISO9001, ISO14000, and OHSA45001.

The company has 60000KN, 80000KN, and 120000KN ultra large injection and pressure equipment, with the largest tonnage of oil pressure machines in the industry and multiple three axis machining centers and several five axis machining centers, making it the first enterprise in the industry to use five axis machining.

The unique raw materials and formulas for filter plate manufacturing ensure various performance indicators and mechanical strength, and the material is uniform and dense. The company has passed three major management system certifications: ISO9001, ISO14000, and OHSA45001.

Largest tonnage of oil pressure machines in the industry

Five axis machiningcenter

(first one to use in the industry)

Five axis machiningcenter

(first one to use in the industry)