Basic Info.

Model NO.

HR

Voltage

380V/50Hz 3phase Can Be Customized

Load Capacity

1000-2000kg

Certification

CE, ISO9001: 2000

Warranty

1 Year

Customized

Customized

Condition

New

Machine Item

High Temperature Pressure Jigger

Machine Painting Color

Be Made According to Your Need

Price

Lowest Reasonable Offers in The Market

After-Sales Service

24 Hours Technical Support by Email, Call, Video

Warranty Time

Offer Free Spare Parts and Service Within 12 Month

Working Experience

32 Years′ Experience

Delivery Date

Fast Delivery in 30 Days

Power(W)

45kw

Length of Tube

1200-2000mm

Steam Working Pressure

0.3MPa

Heating

Direct Steam/Indirect Steam

Dimension(L*W*H)

13860*2980*2650

Length of Hank

820mm

Max.Working Temperature

98 Degree

Transport Package

Standard Package or Nude Package Customized

Specification

Dimension(L*W*H): 13860*2980*2650

Trademark

HUARUI

Origin

Qingdao City

HS Code

8451290000

Production Capacity

100/Week

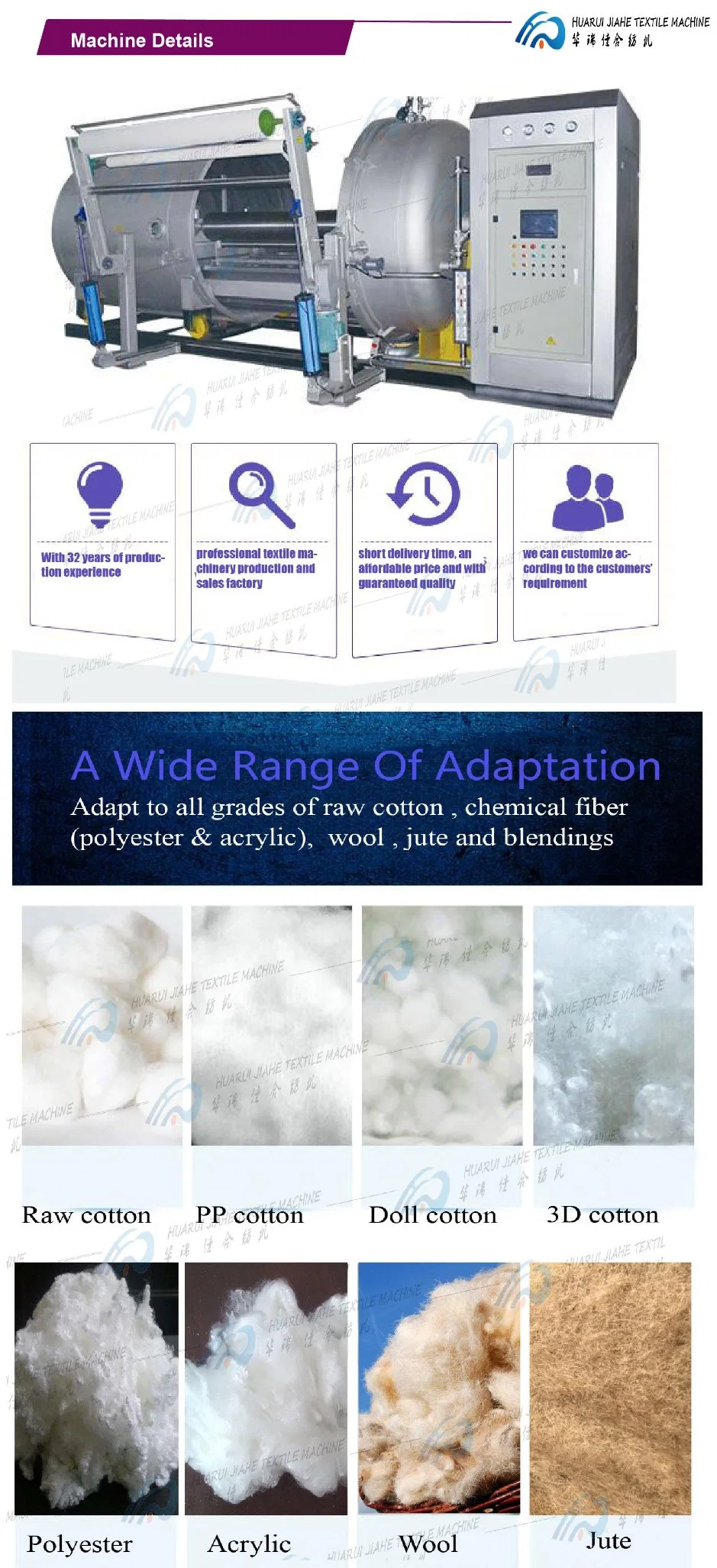

Product Description

Brief introduction:

Technical features:

Adopting AC frequency invert driving, PLC contorl and data communication technology.

Truly direct fabric surface tension, linear speed inspection and closed loop control.

Utilizing the touch screen technology. Excellent man-machine dialogue function.

Auto temperature control, auto direction reversing, auto stop and fabric swing function.

The dye liquor circulation system of the machine can make the temperature of the dye liquor be the same and make the dyestuffs be even distributed.Equipped with filtering device to prevent the blockage of the piping.

Heating protect device ensures the temperature rising speed to promote the production efficiency.

The entire machine is equipped with auxiliary devices such as overhead casing illumination lamp,breakage alarm lamp,emergency stop rod,etc.Safe operation,easy maintenance.

Water discharging valve,air chimney and fabric delivery's crossbeam are controlled pneumatically.

The main components of this machine are imported to ensure the stability and reliability of this machine.

Full automatic control of the production can realize various kinds of technology combination.

The cover opening is flexible and convenient. The body can slide on the guiding rail smoothly.

Detail machine pictures, all photoes are for 100% real shooting ! For more pictures, video and details, please email me!

Specification

| Diameter of main roller | φ245-325mm |

| Max.diameter of cloth roll | φ800-1200mm |

| Max.Working fabric width | 1800-3400mm |

| Adjustable fabric rate | 0-130m/min |

| Tension of fabrics | 0-90kg |

Control Function:

The whole machine is a double frequency conversion control system, man-machine operation interface .

Realize constant tension and constant linear speed setting.

Manual, automatic, acceleration, deceleration functions.

It has the functions of automatic head-turning, automatic track counting, automatic parking, and automatic lane full swing.

Automatic temperature control of the whole machine with process operation.

Operation screen programmable setting, process storage, automatic identification, automatic alarm.

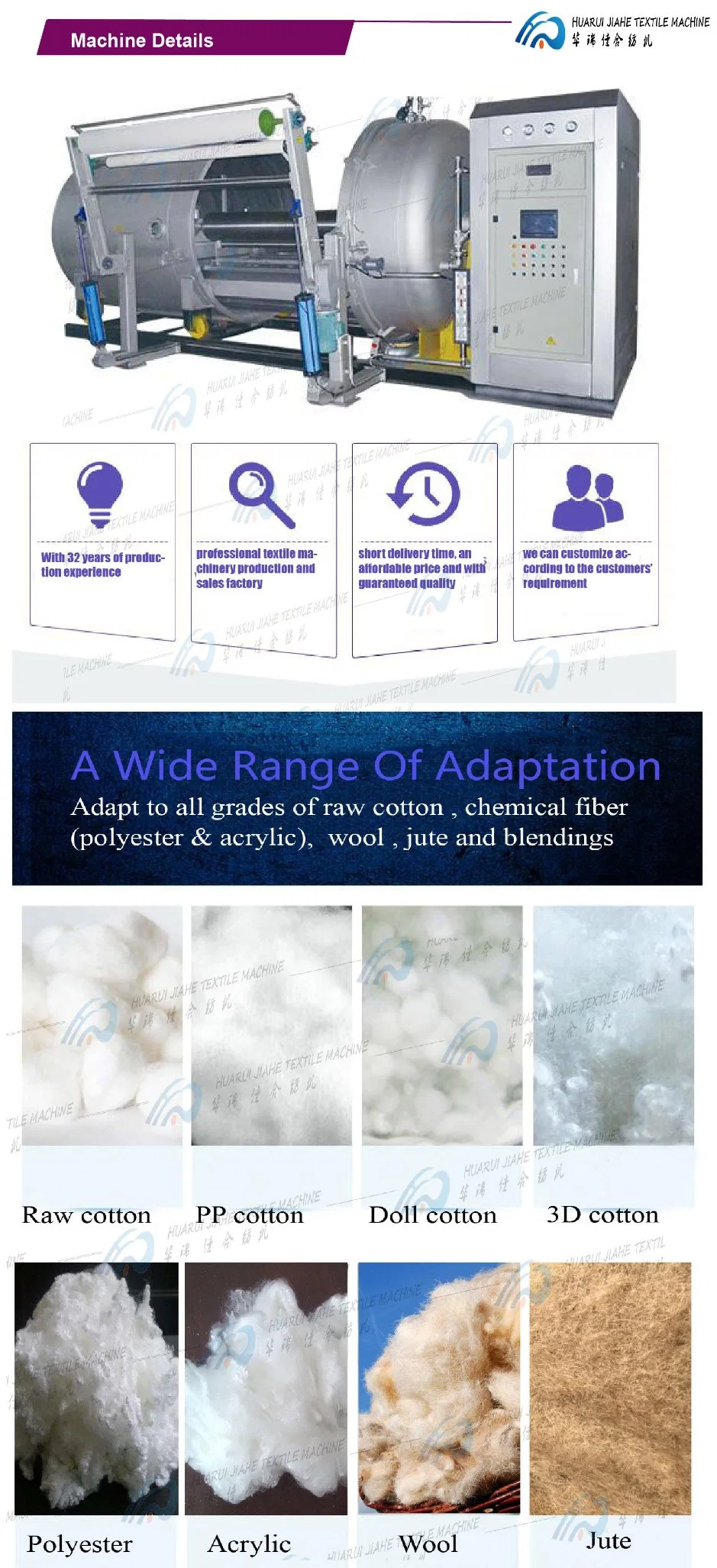

Mainly for open width nylon,spandex, sllk, desizing, bleaching, scouring, dyeing, etc of fabric of cotton,polyester, flax and blended fabric.It can be widely used in the dyeing and printing industry to meet the requirement of small batches and different kinds.

OUR ADVANTAGES

1) Excellent, high corrosion-resistant stainless steel

2) Ultra-low bath ratio , Wisdom, energy saving and environmental protection

3) Humanized design Automatic lifting bracket

4) Automatic feeding system Precision feeding

5) Direct heating and indirect heating combined

6) Won the invention and utility model patent certificate